Product category: Lifting & Tipping

new Equipment

Available

ATEX Bin Tipper

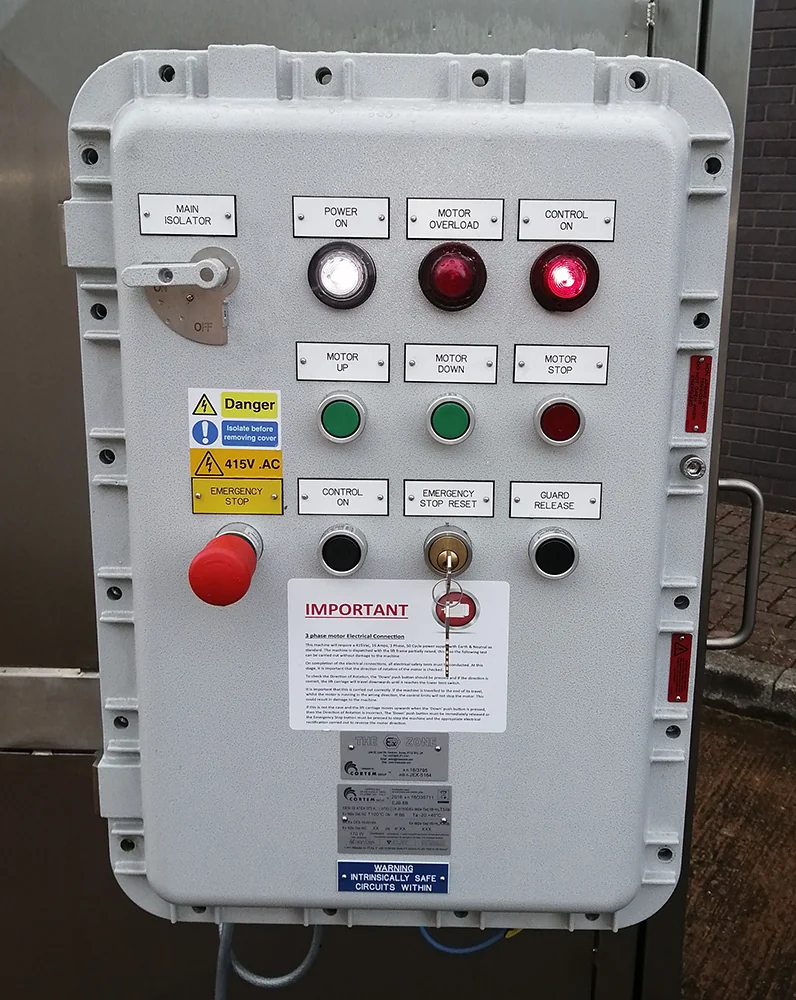

BTM/300/2500/M Single Pillar ATEX Bin TipperThe ATEX Bin Tipper was designed to lift and tip at a discharge of 2500mm giving an overall height of approximately 3548mm. The wetted herb material would be tipped into an intermediate hopper that will ensure that there is no spillage during the tipping process. The ATEX Bin Tipper is manufactured from Grade 304 stainless steel, is a welded construction throughout and is designed to be mobile on two fixed and two swivel braked castors. The ATEX classification for the area in which this lift was installed was ATEX Zone 1 T2 IIB. All components and materials used and the design of the lift conformed to the requirements of this ATEX Classification. For this ATEX area classification, the ATEX Bin Tipper was independently evaluated for conformance to the relevant ATEX standards. ATEX Bin Tipper Electrical ControlThis ATEX Bin Tipper is fitted with an IP65 ATEX Control Panel which is mounted on the main column at a convenient position to give good maintenance access under the Provision and Use of Work Equipment Regulation 1998 (PUWER). The unguarded ATEX Bin Tipper has ‘dead man’s handle’ control such that the ‘Up’ or ‘Down’ pushbuttons must be held for the ATEX Bin Tipper to operate. As soon as the button is released, the ATEX Bin Tipper will stop. The control panel has the facility for a ‘Call to Run’ signal to be connected if required. |

Distance: 5,762 km away

Description

Single Pillar ATEX Bin Tipper

Model No.

BTM/300/2500/M

Capacity

300 Kgs

Tipping Height

2500mm

Tipping Angle

130 Degrees

Overall Height

3483mm

Machine Handing

Left Hand

Maximum Headroom

4000mm

Tipping Chute

No

Intermediate Hopper

Yes

Container Description

200 Litre Tote Bin

Base Arrangement

Mobile On Castors

ATEX Classification

ATEX Zone 1 T2 IIB

Control Circuit

24Vac

Electrical Rating

IP65

Limit Switches

ATEX Zone 1

Motor Detail

0.75kW, 415V, 3 PHASE, 50 CYCLE c/w BRAKE

Gearbox Detail

SEW Eurodrive

Output R.P.M

28 R.P.M.

Ratio

50:1

Load/Lift/Tension Chain

¾" Simplex

Tensile Strength

3000 Kgs

Lift Speed

6.4 Meters/Minute