Product category: Lifting & Tipping

new Equipment

Available

Pallet Lift

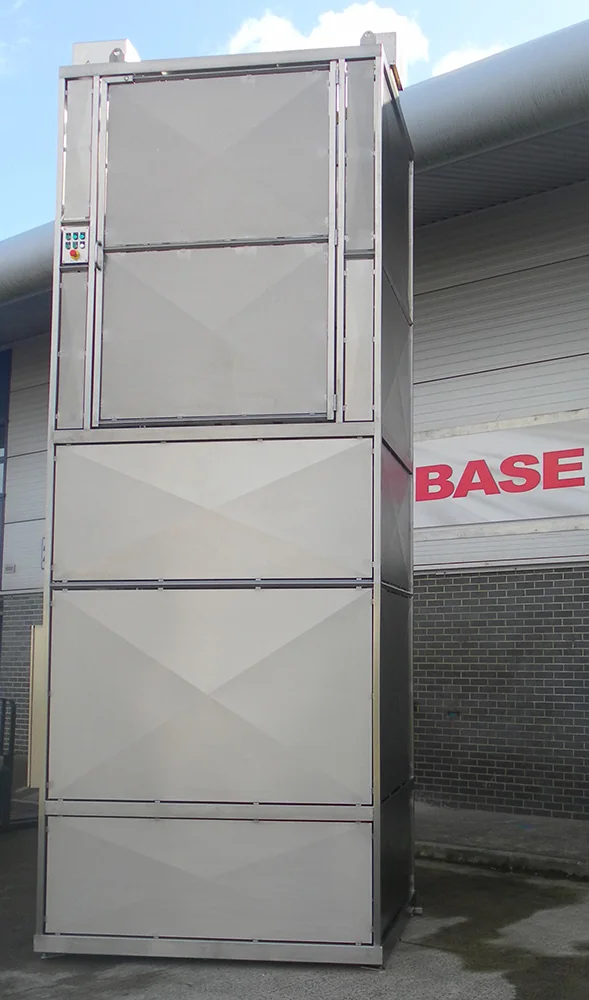

PLM/2P/1000/3042/B/G Double Pillar Pallet LiftThis Double Pillar Pallet Lift has a Safe Working Load of 1000 Kgs and a lift height of 3042mm. The lifting platform will be large enough to accommodate a standard pallet (1200 x 1000mm x 1500mm high) to be loaded using a hand pallet truck, through the front of the Pallet Lift. At the upper level, there will be a landing plate to allow easy unloading at the rear of the Pallet Lift. The Pallet Lift will be constructed from Grade 304 stainless steel and is fully welded throughout. The Pallet Lift is designed to be bolted to the floor without the need for a pit. The lifting is accomplished via chains driven by a motor gearbox mounted at the top of the one column with a crossover shaft to the other column. Safety Guard to BS EN 14120:2015 Safety of Machinery GuardsThe safety guard is constructed from 40 x 40 x 3mm stainless steel box section and 2.0mm stainless steel sheet to meet the guidelines of BS EN 14120:2015 Safety of Machinery. This guard will reach to a height of 2200mm above the upper floor level, having a hinged door at each level through which the Pallet Lift can be loaded and unloaded. Each door is electrically interlocked to prevent the Pallet Lift being operated with a door open and in addition, the doors are mechanically locked closed whilst the Pallet Lift is running. Each door may only be opened when the lifting carriage is at the appropriate level. Pallet Lift Electrical ControlThis Pallet lift is fitted with an IP65 Stainless Steel Control Panel which is mounted on the safety guard at a convenient position to give good maintenance access under the Provision and Use of Work Equipment Regulation 1998 (PUWER). The control panel incorporates the following controls; Up, Down, Guard Release, Emergency Stop, Cleaning Key Switch and a Reset Facility. There will be a remote Stainless Steel push button station at the upper level incorporating the following controls; Up, Down, Guard Release and Emergency Stop. Dual Upper and Lower end of travel limit switches are positioned to prevent inadvertent adjustment or damage but are easily adjustable by trained personnel for fine adjustment on site. The Pallet Lift operation is latched so that pressing the respective ‘Up’ or ‘Down’ push buttons once will raise or lower the lift to the other floor level. Each time the Lift Carriage activates the upper limit switch, an electrical actuator will be driven out underneath the lift carriage to support it while it is loaded. Before the lift can move again, the actuator will retract automatically once the down button is pressed. Pallet Lift Cleaning SystemThis cleaning system will be fitted to the Pallet Lift during manufacture to allow access to the floor beneath the lift carriage for cleaning. The cleaning system will operate as follows:-

|

Distance: 5,762 km away

Description

1000 Kgs Double Pillar Pallet Lift

Model No.

PLM/2P/1000/3042/B/G

Lift Height

3042mm

Overall Height

5739mm

Platform Size

1300 x 1100mm

Maximum Headroom

6000mm

Container Description

Pallet (1200 x 1000 x 1500mm High)

Base Arrangement

Bolted To The Floor

Control Circuit

24Vac

Electrical Rating

IP65

Limit Switches

Telemecanique

Gearbox Detail

SEW Eurodrive

Motor Detail

1.5kw, 415V, 3 PHASE, 50 CYCLE C/W BRAKE

Load/Lift/Tension Chain

1" Simplex

Tensile Strength

6000 Kgs, 3000 Kgs

Tension Chain

¾” Simplex

Lift Speed

6.4 Meters/Minute